Ter-ra solutions by Pavimenti Sansone allow the creation of elegant, precious surfaces, distinctively enhanced by the extraordinary value only

a handcrafted creation can provide.

Added value for anyone seeking something unique.

Cement is the most valuable element of a floor or facing, able to bestow a special touch to your surroundings.

For this reason, due to the materials of which they are made Ter-ra solutions by Pavimenti Sansone imbue all of your spaces with a unique elegance, succeeding in melding different aesthetic and technical qualities in public and private settings: from homes to offices, from doctors’ offices to restaurants, and from shopping malls to museums.

Ter-ra solutions by Pavimenti Sansone are produced by skilled craftsmen, true artists who know the best techniques for working with cement, and are installed by expert technicians capable of enhancing the material’s beauty and utility with great care and respect for detail.

If you are searching for something unique, choose Ter-ra cement mortar by Pavimenti Sansone.

Beautiful, inimitable. Genuinely Ter-ra Cement Mortar by Pavimenti Sansone.

Mortar has a wide range of applications, as do the substrates on which it can be applied. The microcement guarantees impermeability, UV resistance, and resistance against chemicals. That is why, in addition to covering floors, it is particularly suited for humid areas of the house, such as walls and shower trays.

Ter-ra cement mortar by Pavimenti Sansone comes in thirty-two shades, with colors ranging from earthy brown to wheat beige, from moss green to sky blue, without neglecting the natural tones of cement with all its shades of white, gray, and black.

All the color pigments used are natural oxides.

When choosing a home to buy or renovating a house, a couple considers trends when selecting the floor.

Whether it’s parquet, porcelain gres, or tile matters little, the material selected has to be the main focus of the home.

In addition to the materials listed above, another material more familiar to industry insiders than end-users must be considered, and that is cement.

Cement is a modern, versatile and durable material. Usually, when you think of a cement floor, an industrial surface, perhaps associated with a garage or exterior, comes to mind.

However, besides being a very versatile material, cement lends itself to multiple types of applications. A modern and desirable solution. Cement cladding has been the most popular choice in interior design trends in recent years. In fact, an ever-increasing number of designers are suggesting more rudimental lines of solutions and natural materials that enhance the friendliness of the surroundings and render them more and more aesthetically appealing. Indoor cement floors are certainly among the most successful. They fit in perfectly in both industrial settings and contemporary homes but are just as pleasing in rural settings or country-style homes in which you want to add a touch of originality.

The coatings are composed entirely of cement, a material that was considered a durable building material with no aesthetic appeal until just a few years ago. But now, because of its versatility, the material has been notably reappraised, especially for interior flooring. In fact, cement flooring can easily be applied on any indoor surface and is readily found in various finishing, accommodating any style or taste.

What are the pros and cons of concrete flooring?

Cement surfaces have several advantages.

The first is craftsmanship. The floor is handmade without the use of mechanical equipment.

This is indeed a customized accomplishment, creating a single slab over the entire space. This facilitates the installation, which will undoubtedly be easier.

Good craftsmanship means the surfaces can be customized to suit your tastes in terms of aesthetics and from a technical perspective.

The large variety of stylistic solutions enables the surface to adapt to diverse spaces without the utmost ease.

Another advantage is the absence of seams.

Concrete floors, with their seamless appearance, are easier to clean than parquet or tiled surfaces. Seams also accumulate dirt, making the floors unhygienic.

Customization is another advantage of concrete flooring.

Ease is a key factor in laying cement flooring. Floors of this type can be laid on top of an existing floor. A cement floor is laid in thickness of just a few millimeters.

Furthermore, application requires only a few hours of work that can be accomplished quickly without overly invasive interventions.

The selection of indoor cement flooring is considered environmentally friendly, being that the solution entails water-based products. For this reason, it is deemed as compatible with current European Eco-sustainability regulations. Not only beautiful aesthetics but respect for the environment as well.

It has its advantages and drawbacks.

The first disadvantage regards the application.

Floors of this type do not lend themselves to do-it-yourself work. Quality laying requires the work of skilled craftsmen with the skill necessary to lay a perfectly smooth surface. Failure to install the floor properly can result in quite a few problems that negate the benefits, usability, and aesthetics of what would otherwise have been a beautiful cement coating.

Another disadvantage entails potential damage to the surface. In some cases, a surface could become damaged by cracks and breaks. In these cases, which are very few and far between, a new coat would be needed for the entire surface because minor retouches would stand out and certainly appear ugly.

This problem won’t happen, though with Ter-ra cement mortar by Pavimenti Sansone: everything doesn’t need to be redone, and the touch-ups are, to all intents and purposes, imperceptible to the naked eye.

Don’t forget that cement is very durable, and the risk of breaking or cracking is extremely remote.

Last of all is cost. Cement, in many cases, is not cheap because it has to be manually laid by skilled tradesmen to prevent future problems.

What are the various types of cement floors?

There are several types of cement floors.

Industrial concrete is very thick and is laid in sections with joints to avoid potential cracks and crazing. They are laid using mechanical equipment.

Spatula-applied concrete is formed from a special mixture of pure material, and a thin layer is laid. Thanks to the fiberglass reinforcement with which it is laid, it has a high resistance to cracking. The spatula effect is achieved thanks to the manual workmanship that makes each floor unique and one-of-a-kind.

Cementitious resin , instead, features a two-component system that provides a superior hardness to elasticity ratio, making the formation of cracks and fissures more difficult. It also has better value for the money than traditional resin. Cement floors must always be laid by professionals.

Large surfaces (with an area greater than 100-150 square meters) offer the most favorable economic ratio; the greater the surface area, the more convenient the price.

Colors

Microcement comes in a range of basic colors in the catalog. Nevertheless, upon request, you may choose your favorite color, even from those not included in the catalog.

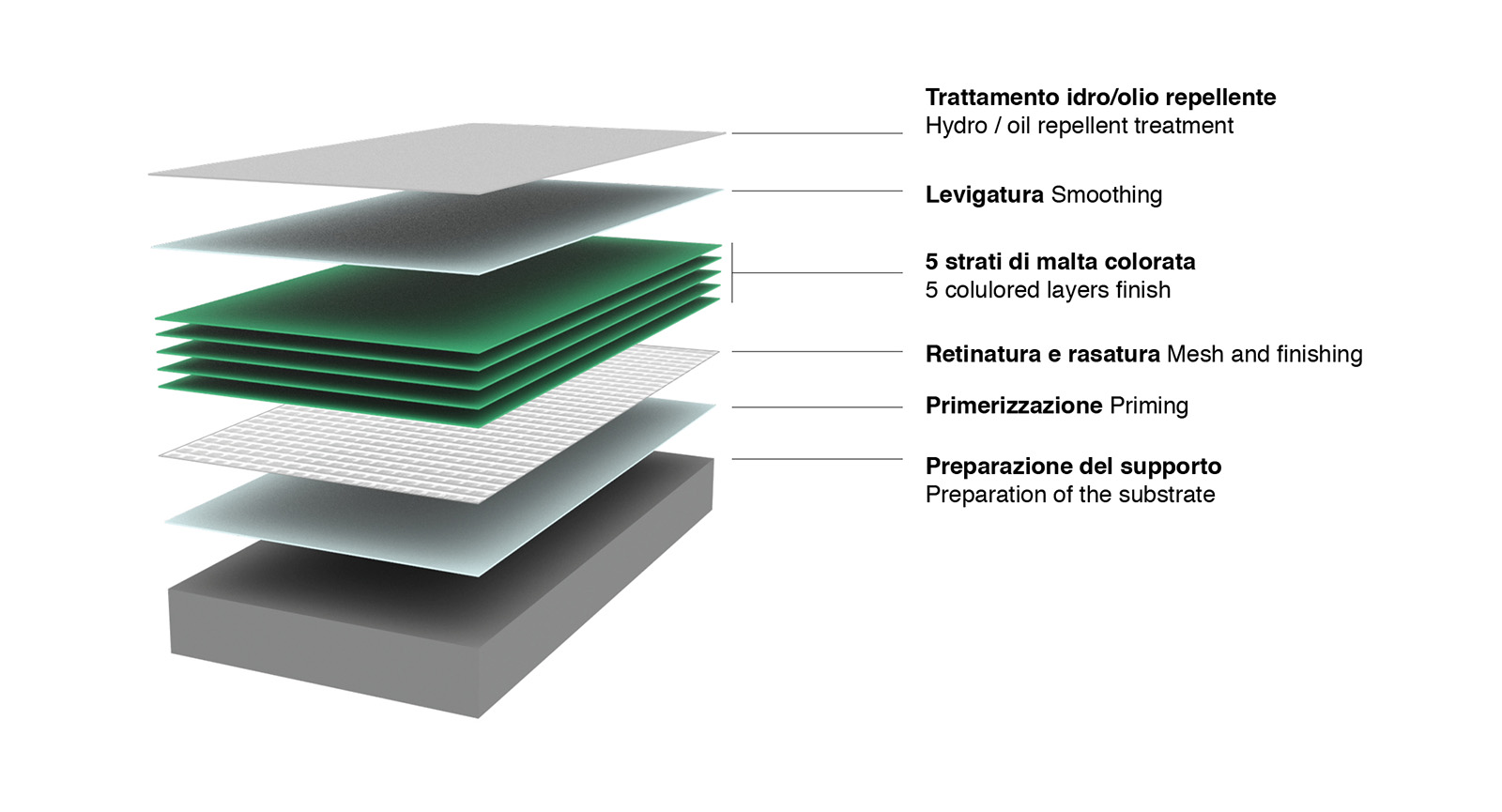

Stratification

Colored cement coating for floors.

Stratification improves the floor’s imperviousness to dust, rendering it impermeable to water, oils, hydrocarbons, and liquid substances used in food preparation.

Increases resistance to surface abrasion.