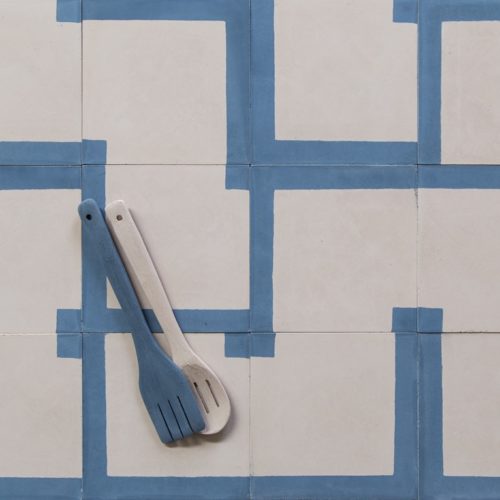

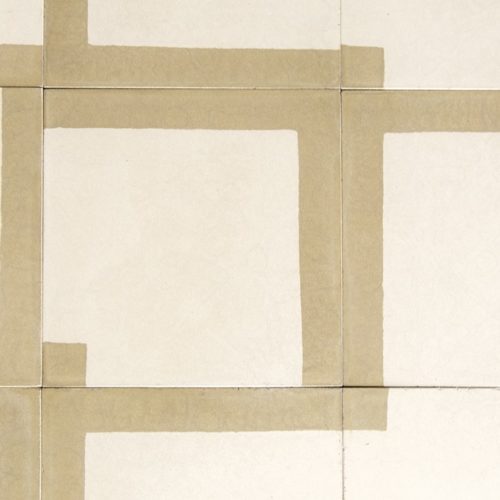

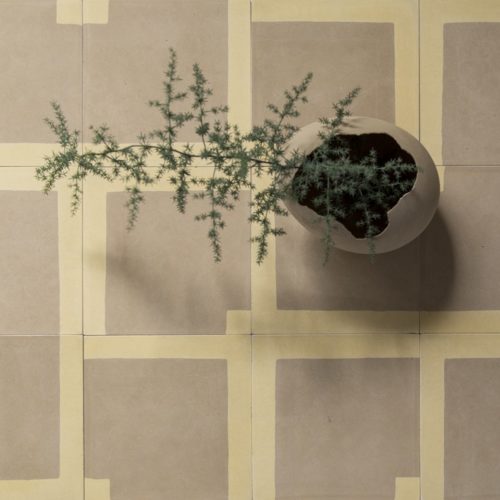

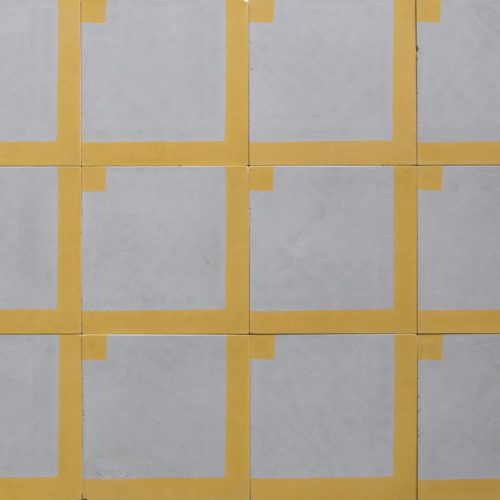

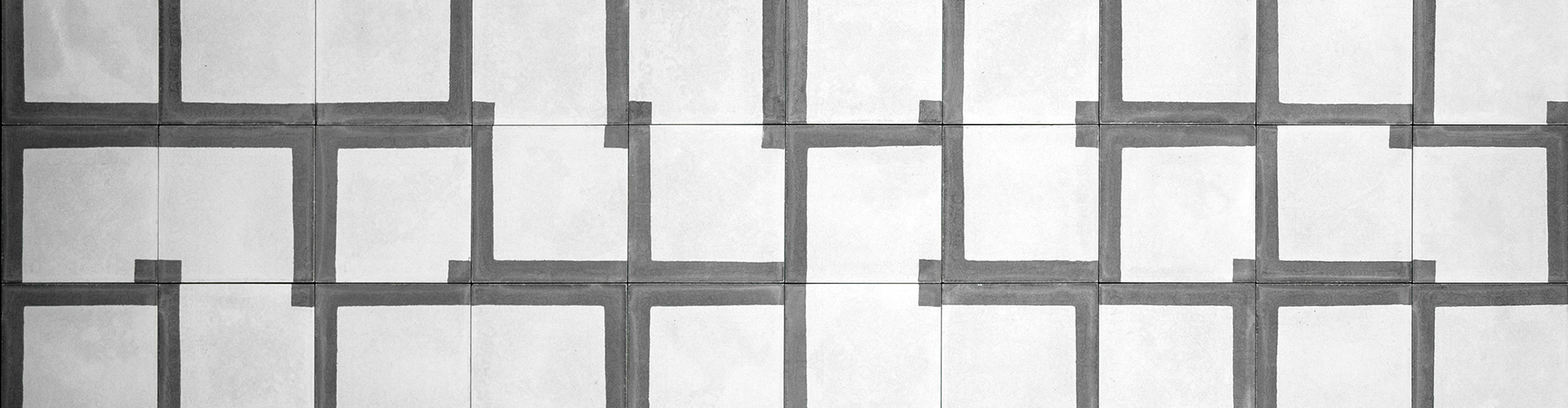

The Rewind project started with reorders of Pavimenti Sansone’s most antique collections of cement floor tile.

The archiving and cataloging work performed on the entire set of casting trays and colors used over the decades inspired the “revival”

of the cement floor-tile-tradition with a modern interpretation.

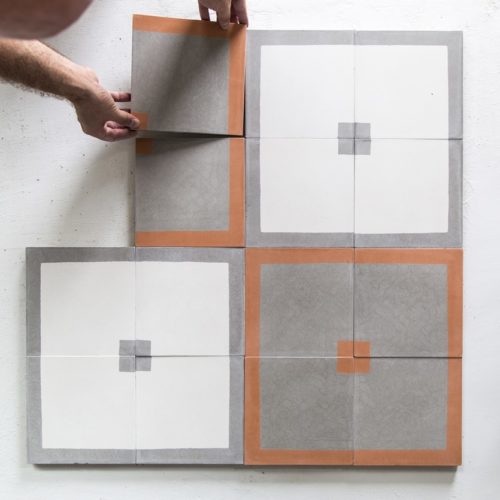

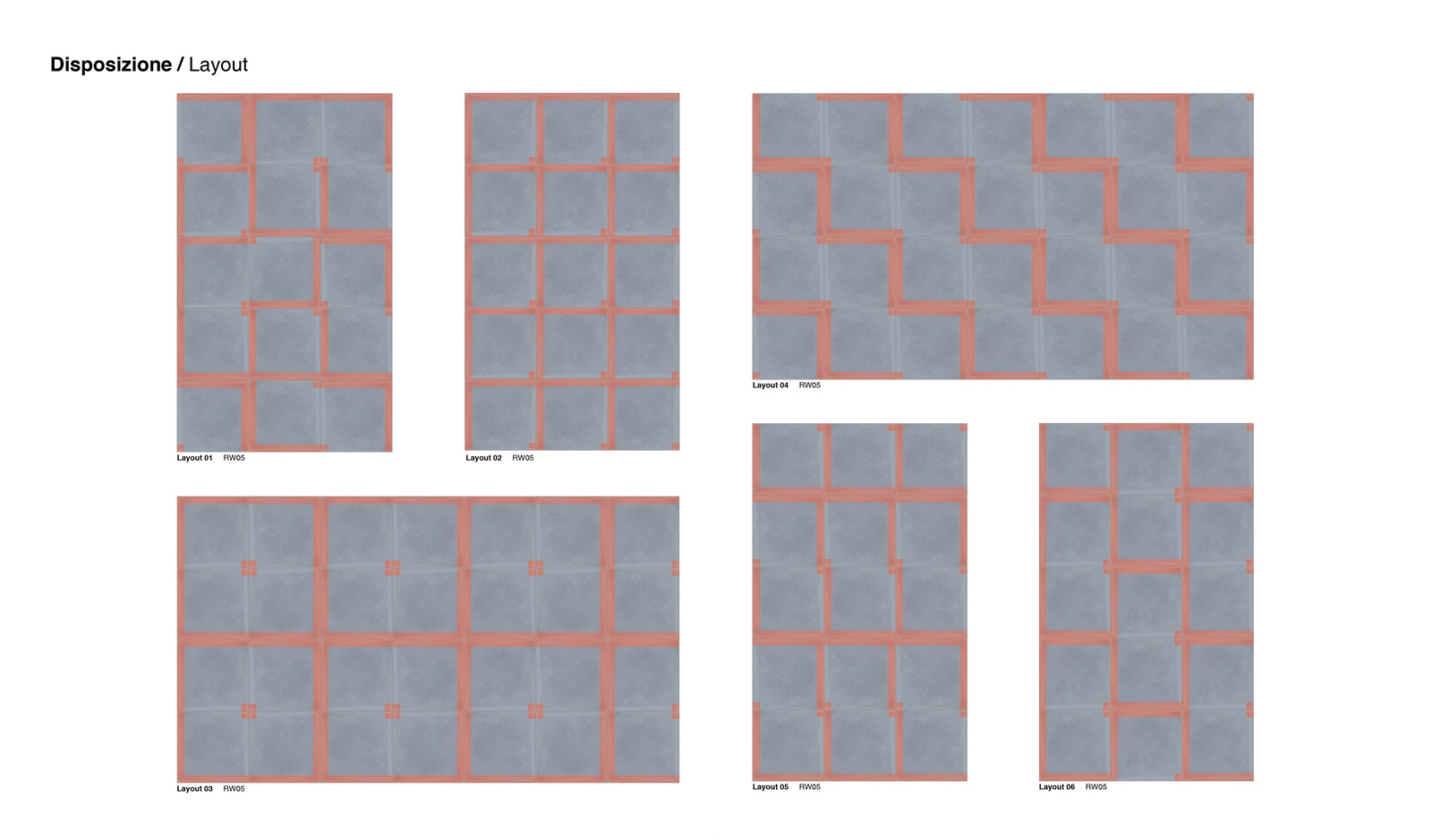

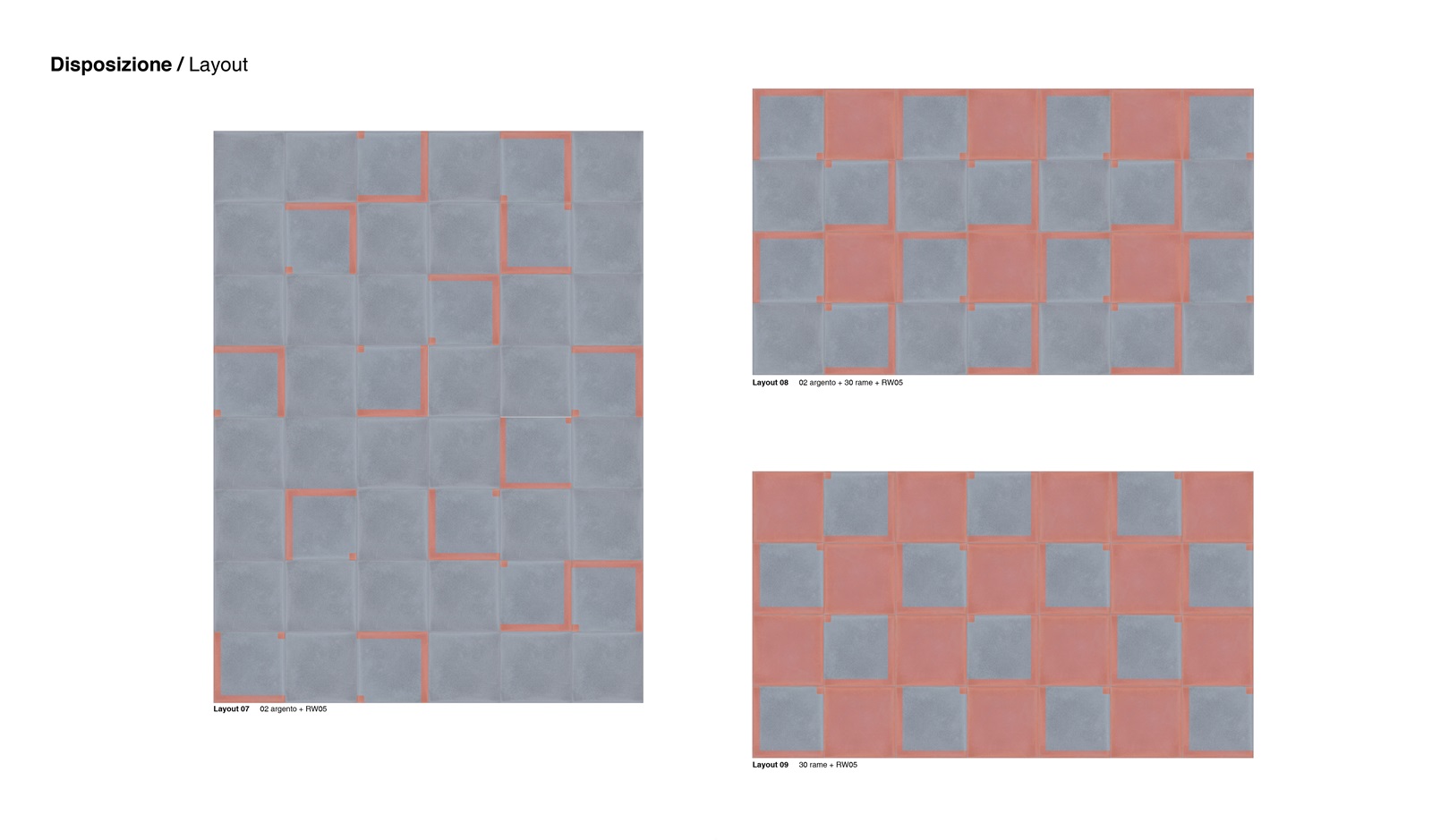

Minimizing the decorative features results in the composition of a cement floor tile having a different pattern each time: random or desired.

Design by Jpeglab

Technical area

Product features

The variation of dimension and colour, the micro holes on the surface are within the tolerance of a handmade manufacturing process and, for this reason, to be considered distinctive features of the product itself.

General warnings

Avoid stocking material open-air to prevent rain water soacking the packaging and damaging the materials.

Install the tiles as soon as possible and do not leave the product at prolongued exposure to sunlight to prevent efflorescence or tone fading on the tile surface.

Directions for use

“Rewind” collection is intended for internal and covered external use only, because the prolonged exposure to UV rays can change over time the colour tone of the tiles. “Rewind” floor should not be sanded.

Substrate

The substrate must be compact, flat, free of oil, grease, roughness, dust and debris.

In case of cracks in the screed, it is highly recommended to fix them with suitable products. Allow the cement substrate to dry properly. Carefully remove any possible remaining damp off the installation areas and avoid laying “Rewind” on wet surfaces.

Installation

It is recommended to install “Rewind” using cement-based adhesives such as Pavimenti Sansone FLEX-CEM600. Any glue excess either on the tile surface, or on the joint, must be removed. It is recommended to keep 0,04” gap between the tiles.

Cleaning

Cement tiles are not resistant to acids, that even diluted tend to attack them. Do not use acids for the first cleaning after installation. It is recommended to wash the surface evenly, with Pavimenti Sansone CLEAN-DTG cleanser. Use mono brushes with no abrasive disks. Mop up the floor uniformily and clean any remaining liquid.

Rinse with plenty of clean water and let it dry completely.

Treatment

On floor completely dried, and with no humidity halos, evenly spread two water-repellent coats of Pavimenti Sansone IDROREP-RK product, avoiding any product excess, then let it dry. Carry out all operations by qualified installers only. Try the tiles before installation.

Grouting

For grouting it is recommended to use the FUGA-CEM product by Pavimenti Sansone. It is advisable to grouting by qualified personnel.

Finishing

After cleaning the floor off any grout remains, lay an extra coat of water repellent IDROREP-RK product uniformly. Let it dry. After drying, finish it with a further coat of wax, following the wax manufacturer’s instructions.

Regular maintenance

Use neutral detergents. Never bleach or use aggressive acids or alkali cleaning agents. The surface should be waxed regularly, following the wax manufacturer’s guidelines.

Weight and dimensions

Square

Thickness

Weight

Pieces per pallet

Quantity per pallet

Weight per pallet

8”x8”

~ 8”

~ 1.6 kg

500

20 mq

~ 800 kg

Technical features

Length and width

Thickness

Straightness of sides

Identification

Characteristics

Physical properties

Resistance to dynamic loads

Rbk

Breaking load

Wear resi stance

Toxicological information

Water absorption (treated tile)

~ 0.2 %

~ 0.2 %

~ 0.2 %

CM1 Cement, sand and marble

High chemical and physical resistance to environmental polluting agents _ High resistance to UV rays

Washable _ Installation temperature from +5° C to +45° C

covers a wide range of vibration stresses, given the homogeneity of the material

500 kg/cmq

600 kg/cmq

85 kg/cmq

None

0.1 %

Installation products and maintenance

Detergent

Grout

Water repellent

Adehesive

Joint

CLEAN – DTG

FUGA – CEM

IDROREP – RK

FLEX – CEM 600

1 mm